AIA Continuing Education + Additional Resources

Looking for a way to learn more about masonry or fenestration? We offer over 40 AIA-accredited continuing education courses! Check out our "menu" of offerings here, and contact genesisl@bricksinc.net to schedule. We offer informal lunch & learns, brickyard tours, virtual sessions, office visits, and more — to groups of any size and any background (architects, homeowners, masons, builders, contractors, designers, etc). Reach out and let us know what you want to learn!

— Check out AAA-1 Masonry's masonry vocabulary guide, which explains common terms & has tons of great advice about caring for your brick.

— Our friend at Brick of Chicago has many great educational resources about brick and its history available.

— Masonry of Denver has many great blog posts and a wonderful masonry glossary.

— How was brick made, and how did the process change over time? Check out this blog post by Old Carolina Brick for an in-depth answer.

— There are many wonderful educational resources on the Brick Industry Association's website.

— The International Masonry Institute has a great library of illustrated construction details and diagrams for masonry systems.

— BLDG Projects has a great blog addressing common architectural concerns for Chicago homeowners. Check out their posts on accessory dwelling units, plat of surveys, common building violations, and wintertime construction tips.

— Check out this great write-up about Chicago common brick by the Chicago Reader.

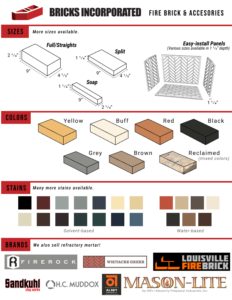

Brick Sizes

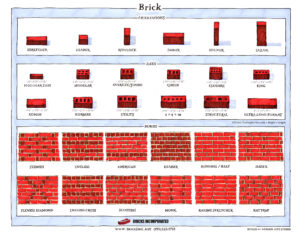

There is no such thing as a "regular," "standard," or "normal" brick. To quote architectural scholar Tom Leslie... "Different cities make different bricks; in reality the products of no two brickyards are entirely alike in size, nor, for that matter, all bricks burned in the same kiln." Brick manufacturing has been happening worldwide since 3,500 BCE! Over time, standardized sizes have changed — and they still vary by country, region, and manufacturer. By the late 19th century, the "Chicago Common" brick measured roughly 2"x4"x8". Nowadays, new US "modular" brick (the size you're most likely to consider "normal") measures 3-5/8" x 2-1/4" x 7-5/8".

All of this is to say: MEASURE YOUR BRICK! Especially if you're trying to match an existing brick. Brick dimensions are traditionally written Depth x Height x Length. For more detailed information on commonly used brick sizes, shapes, orientations, and grades, click here.

How Much Brick Do I Need?

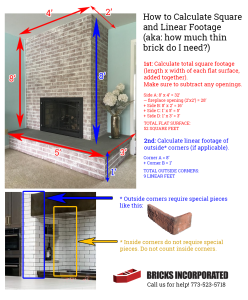

How much brick you need depends on three main things: the size of the area you are trying to build or infill with brick, the size of brick you're going to use, and the size of the mortar joint you would like to use (a standard mortar joint is 3/8"). You also have to factor in about 3-5% waste... bricks do break from time to time! Here's a useful calculator for you to use.

Measuring for thin brick? You'll need to count total wall area in square feet, plus linear feet of any outside corners. We have a helpful graphic for you to reference that explains it.

Brick Matching & Custom Brick

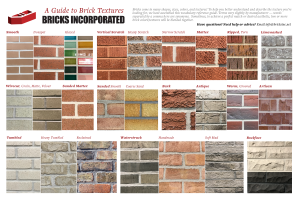

At Bricks Incorporated, we specialize in providing brick that can closely replicate existing brick. Whether you're doing repairs, building an addition, or seeking out a similar brick to one you saw on Pinterest, we've got your back! Here's a step by step guide that explains what we'll need from you, and how the process works. View or bookmark our Instagram post on this topic.

- 1. Measure your existing brick! Remember, provide dimensions in Depth x Height x Length when the brick is laying broad, flat-face-down like it would in a wall. Take some good photos of your brick as well... both a closeup and a picture of the whole wall.

- 2. If you need a large quantity (think 1,000 or more), our sales team will assist you. Email your photos, dimensions, and approximate quantity needed to info@bricksinc.net to begin. Alternately, you can visit our Chicago showroom and compare your brick to our 400+ display panels! Once your salesman has identified a handful of good candidates, we'll deliver some samples to you so you can compare directly to your existing brick. When the winner is selected, we’ll order it for you from the manufacturer. We can even talk you through the pricing for ordering custom-made brick to match!

- 3. Now, if you just need 10 bricks, or a couple hundred, we’ll usually have you browse what’s in stock in our yard instead. It’s cheaper, faster, and easier for you that way. Our brickyard staff have encyclopedic knowledge of our 20,000 sqft property... with product dating as far back as the 1970s! Many treasures abound, and they can guide you to various options that could work for your needs. If you live close by, you can head directly to our location to start the process. Live far away? Send photos, dimensions and approximate quantity needed to info@bricksinc.net for a quick response letting you know if it's something we have workable matches for.

How to Describe Masonry You Like or Desire

Found an inspiration picture on Pinterest or Instagram, and want to see other options like it? Struggling to describe the look of a unique brick you like, or have on your home?

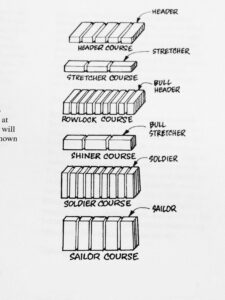

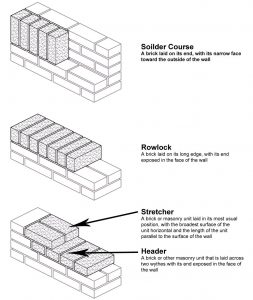

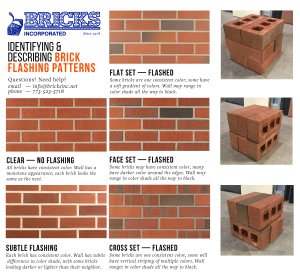

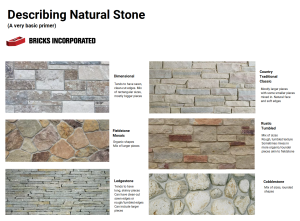

Email us a picture, and we can help you describe what you're looking for. You can also reference some of the visual guides we've made: check out our reference guides to describing brick texture and flashing, our illustration of different brick sizes, orientations, & bond patterns, or this basic primer to natural stone appearance. We also love this "Stone 101" guide from Champlain Stone, which has a ton of great diagrams, vocab words, and explanations relating to the quarrying and look of natural stone.

All About Mortar

- What should I know about mortar?

On a well-built masonry wall, mortar should act as the sacrificial substrate. As architectural conservator Jennifer Cappeto explains, "Moisture is inherently lazy: it seeks the path of least resistance." Ideally, the mortar you choose should be made of a softer material than the masonry it holds together. That way, when moisture travels down or through your wall, it is drawn to the soft pores of the mortar joint. During the freeze-thaw cycles of wintertime, the expansion of that moisture into ice will slowly break down your mortar, rather than your brick. The process of grinding out and replacing mortar joints is called "repointing" or "tuckpointing," and is a routine, necessary procedure that should only need to take place about once every 25-30 years. Here are a few more helpful pieces of advice about tuckpointing, and here's a step-by-step guide for ambitious DIYers. - A note on ideal mortar strength and application

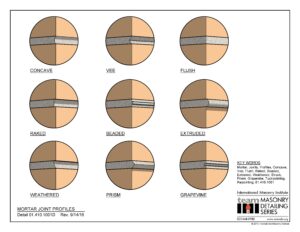

Not all masonry walls are built using a suitably soft mortar, and not all mortar joints are pointed correctly. Read more about the dangers of using a mortar too strong for your brick, and how to know what parts cement/lime/sand to use for your brick, by clicking here. Badly or sloppily pointed mortar joints can also pose a problem for your brick. A mortar joint "profile" describes the appearance of the mortar — click here for a diagram of different mortar joint profiles. Generally, any mortar joint that bulges out past the profile of your brick, such as an extruded joint, can cause damage to your brick. When water travels down the wall, it is drawn to the path of least resistance... which, in the case of bulging mortar, is the surface of your brick. During the winter, this can pose a problem and cause the brick to spall. A concave joint encourages the water to pool in your mortar joint, where it's supposed to be! Just remember: if your mortar looks like buttercream frosting, it's not well pointed. There's even more to learn, including information about the right mortar for common brick, here.

Painting Brick

Please... and we can't say this enough times — don't paint your brick. Brick is a porous substance that absorbs humidity and moisture from precipitation. When left unpainted, this moisture evaporates naturally from the surface of your brick, and through soft mortar joints. However, when you paint your brick wall and mortar, particularly with a latex or acrylic house paint, you trap that moisture inside the wall. Even one winter's worth of freeze-thaw cycles can cause irreversible damage to your brick as the expanding ice microscopically breaks down your masonry. In as little as two-five years, your brick will begin to "spall," and you will need to undertake a costly replacement of your masonry. Read more about why not to paint brick here.

If you would like to change the color of your brick, there are many safe and breathable alternatives to paint. Masonry staining is a great option, as is limewash. Many providers offer both DIY kits as well as connections to trusted professionals who can do the work for you. When selecting a masonry colorant, look for mineral-based finishes advertised as "permeable" or "breathable." Review testing data for the product(s) you select, and ask to visit projects painted 5-10 years ago to see how they've held up. Your brick building will thank you!

Ivy Growth & Removal

Ivy growth is also not great for the long-term condition of your bricks. Although ivy does provide some protection from the elements, shading your brick from rain and sun, the disadvantages of ivy tend to outweigh the positives. Ivy adheres to your wall by sending small growth shoots into the microscopic cracks on the surface of your bricks and mortar, which can then act as a highway for moisture to enter your brick. This can cause problems with efflorescence and lead to moisture-related deterioration. To learn more about the pros and cons of ivy, and how to remove it from your brick wall, please click here.

Efflorescence (salty white residue on masonry)

"Efflorescence" is the term for a build up of salts on the surface of masonry (see a photo example here and here). Efflorescence is generally caused by the presence of water-soluble salts somewhere in your wall, and can vary in appearance depending on which minerals are present. White, powdery residue is most common, usually caused by sulfates of sodium, potassium, or calcium. Efflorescence can vary in texture from fine crystals to hard, limestone deposits, and also appear greenish or brown. As moisture within your wall travels through the masonry and evaporates, the minerals and salts are left behind, causing the "bloom" of efflorescence to appear.

When is efflorescence normal?

— A freshly constructed brick wall contains lots of moisture, and as that water evaporates, areas of efflorescence can appear. Referred to as "new building bloom," the discoloration will typically weather off naturally within a few months.

— Older buildings may experience mild cycles of seasonal efflorescence. Particularly in winter, slow evaporation speeds allow salt to migrate to the surface of the material. Keep an eye on the area; minor blooms should disappear on their own within 60 days or so.

— To speed up the dispersal process, use a soft, dry brush to gently remove the residue. Be sure to sweep it away from the wall, and follow with a low-pressure rinse of plain water.

When is efflorescence a problem?

— Although it is normal for masonry materials to absorb and expel water, a well-constructed brick wall shouldn't experience significant problems with efflorescence. Large or frequent deposits can indicate a moisture infiltration problem caused by cracks, poor construction, or faulty moisture barriers. Read more about recognizing the signs of problematic efflorescence here. Have a mason, inspector, or contractor take a look at any persistent problem areas to address the root cause of the issue.

How do I clean efflorescence?

— Start with the most gentle methods (a soft, dry brush, followed by plain low-pressure hose water). Avoid high pressure washers. Spot test all treatments prior to widespread use. For more information, including step-by-step instructions and product recommendations, read this great Q&A from Masonry Magazine or check out this article. Another great resource is this brochure from the Masonry Institute.

— We do NOT recommend sealing brick to prevent efflorescence. Be careful with all paints, sealants, and coatings. Non-breathable surface treatments can trap moisture and salts within the wall, worsening the issue.

Cleaning Products & Best Practices for Winter

Especially here in the Midwest, the effects of snow, ice, and rapid temperature fluctuations have to be reckoned with on an annual basis. Failing to properly care for your fenestration or masonry products in the wintertime can lead to accelerated corrosion and other damages. Follow these tips to keep your building in tip-top shape for years to come.

MASONRY:

— Don't paint your brick. Check out our section above for a deeper explanation as to why... but suffice it to say, freeze-thaw cycles affect painted brick much worse than untreated brick.

— Avoid oversalting in the wintertime, especially near street-level masonry. Salt slowly eats away at this porous material. Sweep salt away from the base of your building, use brick-safe ice melting alternatives (like beet juice), or even consider sealing the first few courses of masonry with a breathable "graffiti control" repellant from Prosoco.

— Good design is the best prevention! Building your structure with a starter course of hard natural stone (think: dolomite or granite), moisture-impervious protection board, or a permeable "mowing strip" that separates lawns or walkways from the building's base are all good strategies. Check out the Arriscraft Technical Bulletin for diagrams and examples.

— Come springtime, give your building a little TLC by rinsing it with a low-pressure hose and regular ol' water. Avoid pressure washers or corrosive chemicals! Scrubbing with a soft brush or using gentle restoration cleaning solutions from Eaco-Chem should be all you need.

FENESTRATION:

— When fall sets in, check your glass, frames, and hardware for any air leaks, glass cracks, or peeling paint. Apply new caulk or weather stripping as needed, touch up protective paint, or take steps to replace any broken glass.

— Make sure all windows are shut tight and locked to help them insulate better and maintain their shape.

— Implement a regular cleaning schedule to clear minerals and salts off of exterior-facing fenestration. Pay extra attention to aluminum and steel frames, and any sliding tracks or thresholds.

— Watch out for condensation. Ensure good airflow around fenestration (heavy curtains, drapes, and blinds can worsen moisture build-up) and appropriate indoor humidity relative to the temperature outside. Your house should have about 35-40% humidity when it's 20° or warmer, but lower it about 5% for every 10° it drops below that! Check out this handy condensation guide for more information.

Thin Brick, Thin Stone, & Masonry Veneers

- What is thin brick?

"Thin brick" refers to clay bricks that have been cut to a depth of 1/2". Almost all full brick products can be cut thin. Some extruded bricks are purposefully produced at a 1/2" thickness due to the growing popularity of thin brick products. - Is "thin brick" the same as "brick veneer"?

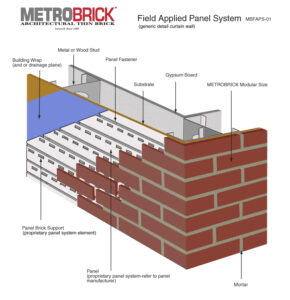

"Thin brick" is a term often used interchangeably with "brick veneer." But, this can create a point of confusion for many people — both construction professionals and regular homeowners alike. Traditional, load-bearing masonry walls were usually two wythes (or layers) thick. Modern construction usually calls for only one wythe of brick, which is then attached to and supported by some other kind of structural system (such as steel or wood studs, or reinforced CMU block). See an example diagram here. Many people refer to that one single wythe as "brick veneer," but the brick being used is usually 3-5/8" thick! For this reason, we prefer the term "thin brick," to describe materials with a maximum thickness of 1". If you have been told to purchase "brick veneer," make sure you clarify what depth you should be buying. - What is thin stone? Is "thin stone" the same as "stone veneer"?

"Thin stone" refers to natural or manufactured stone that has been cut or produced to a thickness around 1/2" to 1-3/4". For comparison's sake, "full bed depth" stone is typically around 3-5" thick. As with the question about brick above, the term "stone veneer" can often refer to either of these thicknesses. If you have been told to purchase "stone veneer," make sure you clarify what depth you should be buying. - How do you install thin brick, or thin stone?

Thin masonry can be installed in a variety of ways. The traditional way is to adhere a metal lathe to the wall, apply a scratch coat of mortar, and then attach the thin bricks (or thin stone pieces) one by one using wet mortar as your adhesive. We recommend using poly-modified adhered veneer mortar for this purpose, which is essentially mortar with extra stickiness. More information on the process can be found here. You can also incorporate thin materials into precast concrete panels. Or, we sell TABS metal wall panels, which can make installing thin brick a breeze! - Why would I buy thin brick or thin stone?

Thin masonry is a popular option for changing the look of your home without a massive renovation. It's lightweight, can be cost-effective, and can be installed fairly quickly as compared to traditional masonry walls. More information can be found here. - Can any masonry product be made "thin"?

Usually, yes. Just be aware there are typically extra charges for the cutting process. - Can I order full-bed-depth product that will match my thin material?

In most cases, yes. Most of our manufacturers offer matching thin and full materials. However, there are some exceptions. Some manufacturers (such as MetroBrick and Summitville) are only equipped to make thin materials. Some thin stones are not offered in full bed depth. Be sure to mention that you need both early in the process so that your salesperson can make appropriate product recommendations. - Is thin material cheaper than full?

It seems like it would be, but not necessarily! Many thin products start out as full brick, so you're essentially paying for a full brick + the cost of cutting it thin. But, some manufacturers have special equipment that can produce brick at 1/2" to 1" thicknesses right from the get-go — their thin products are often cheaper than full brick. It is definitely more expensive to transport full brick, but it can be more expensive to install thin brick. All of this is to say — it often evens out in the end.

LEED, Sustainability, & Green Buildings

LEED is an international, points-based rating system designed to evaluate the "eco-friendliness" of buildings, considering energy use, water use, materials use, indoor environment, building site and location. It takes a minimum of 40 points for a project to be designated a LEED Certified green building, and up to 13 of those points can be earned through building material choice alone! Most commonly, these points are earned by selecting salvaged products, those made with recycled content, or material fabricated within 100-500 miles of the job site.

At Bricks Incorporated, we have been salvaging and reclaiming building materials since 1968 — suffice it to say, our commitment to sustainability and the environment goes way back! We offer reclaimed Chicago common brick, vintage terra cotta, and salvaged clay & granite pavers that can be incorporated into modern designs by homeowners, architects, builders, masons, and interior specialists for LEED credits. Additionally, we are proud to sell Greenleaf Brick, the world's only fired masonry brick and paver line composed of 100% recycled content, as well as Cradle-to-Cradle certified Komproment rain screen systems.

Looking to shop local? We distribute numerous Midwestern-made offerings, including products from Centor, Brampton, General Shale, Endicott, Sandkuhl, Summitville, MetroBrick, and a variety of natural stone producers quarrying throughout Wisconsin. Masonry is one of the oldest building materials on Earth, and choosing brick or stone for your next construction project is an inherent commitment to building timeless, long-lasting, durable architecture. Clay brick is all natural, low-maintenance, versatile, energy-efficient, recyclable, fire-retardant, and nearly zero waste!

And our commitment to ecologically responsible products doesn't stop with masonry. We offer European fenestration lines from Reynaers & EWG, notable for their ultra low U-Values, losing half as much heat to the outdoors as comparable products from domestic manufacturers. Designs incorporating these energy-efficient windows and doors are typically eligible for Passive Building certification. (See an example here.)

— Learn more about LEED from the U.S. Green Building Council's website

— Read more in Masonry Magazine's article "LEED Essentials for Mason Contractors"

— Read about Interstate Brick's industry-leading, clean manufacturing process, or learn how Summitville's responsible raw material mining benefits champion Angus beef cows. Most of our manufacturing partners have environmental impact statements available on their websites.

— Discover how our brick reclamation process works here.

Frequently Asked Questions

-

- Do you have [enter brick name here] in stock?

It depends! We have many colors from the product lines we sell immediately available (just call to check). We can also order most colors/sizes from the manufacturer fairly quickly. If it's not a product line we sell, we can provide a match. Just email us a photo or tell us the manufacturer & color name. - How much does a brick cost?

It depends on size, manufacturer, color, texture, and a litany of other considerations. For an accurate quote, we'll need you to tell us what color, size, and quantity you desire. If you tell us your total budget, we can provide options within your means. The cheapest (modular size) bricks we sell retail for about 30-50¢ apiece. Reclaimed Chicago Common brick sells for 80¢ apiece. A black/white/grey brick costs about $0.90-$1.00 apiece. A fancy, domestic-made brick may cost about $1.50-2.00 apiece. A handmade, Italian glass brick might cost you $30 apiece. There is a wide range, so please reach out for a precise quote. - Do you sell small quantities of brick (0-1000 pieces)?

Yes! We sell masonry for projects of all sizes. Although you'll mostly see larger projects profiled on our website, we work with homeowners, masons, contractors, and other small-time customers on a daily basis. The most cost-effective way to buy brick in small quantities is to peruse what's immediately available in our yard stock. Inventory changes all the time, so the best way to browse & buy is to come visit us anytime we're open! - How can I get brick for cheap?

If you're not too picky about color, we've got a lot of discount brick options. Sign up for our DISCOUNT MASONRY NEWSLETTER or call Roberto to inquire about our cheapest bricks. Inventory changes all the time. It's helpful if you can provide us a specific allowance or budget limit you are trying to stick to. - Do you buy brick?

If you possess a large quantity of Chicago Common brick, please give us a call — we may be interested in reclaiming your brick. Generally, we don't purchase other kinds of brick. - Do you sell mortar?

We stock Spec-Mix Type-N and PMAVM mortar, as well as a selection of their pigment canisters. We can order other types for you, including refractory mortar. - Do you sell stains or masonry cleaners?

We recommend Masonry Cosmetics for staining brick and Romabio for limewashing, but don't stock their products on-site. We have the ability to order you refractory fire brick stains from Sandkuhl. We recommend Eaco-Chem or Prosoco products for cleaning, and can order you some, but generally have limited stock. Call for current availability! - Do you sell chimney caps, flue liners, fire brick, or terracotta wall coping?

We do stock several sizes and colors of refractory fire brick. While we don't actively stock chimney caps, flue liners, coping or other specialty terracotta items, we can order them for you! Call or email to inquire. - Do you sell thin brick or metal panel systems?

We stock thin-cut reclaimed Chicago common brick. We generally don't stock other thin materials, but can order a huge variety of thin brick from our suppliers for you. We can also cut-to-order any of our modular-size yard stock (our wet saw is available mid-March through mid-October, weather dependent). We stock and sell metal panel systems from TABS, including the recommended adhesives and fasteners. - Do you sell concrete brick, concrete block, or CMUs?

We do not sell concrete materials. - Do you sell weeps, wall ties, flashing, or bricklaying supplies?

We carry a selection of masonry accessories from Mortar Net Solutions. Call for current availability and pricing. - Do you sell stone, stone veneer, cast stone, or windowsills?

We sell a huge variety of natural and manufactured stone, stone veneer, and windowsills. While we do not stock stone at our yard, we can order it for you. We stock several standard sizes of Custom Cast Stone in "Natural White," and can order other colors and sizes upon request. - You sell windows & doors?

Yes! We sell windows and doors under our Fenestration Solutions, Inc subsidiary. Check out our Products page for more information. - Do you provide bricklaying, tuckpointing, or window/door installation?

We do not provide bricklaying, tuckpointing, or window/door installation. However, we can always make a recommendation to one of our friends for these services. - What payments do you accept?

Party like it's 1992! We accept cash, check, wire transfers, and money order. - Do I need to make an appointment to see your showroom?

Nope! You can come in anytime we're open. However, if you give us a little advanced notice (2-24 hrs) we will be better prepared to handle your request. - What is the difference between concrete brick, clay brick, and terracotta?

Concrete brick is made from cement. Brick, or clay brick, is made from clay. Terracotta is also made from clay, but it's made with less chunky bits, so it generally has a smoother finish and can be molded into more unique shapes. In Chicago, you often see glazed terracotta facades dating to the 1910s and 20s. - I need a construction waiver. How do I get one?

Please fill out this form to request a waiver. Send the completed form to jessicag@bricksinc.net to request a partial or full waiver. You may also fax the form to 630-897-7057 or mail it to our Aurora location. - What are your shipping/receiving hours?

Our shipping hours are 7am-3pm Monday thru Friday, and — in seasonable weather — 7am-11am on Saturdays. We are closed on Sundays. - How quickly can I get my material?

If the material is in stock at our yard, within 24 hours or same day. If the material is in stock at the plant, generally 7-14 days. If the material is not in stock at the manufacturer, lead times vary widely, so please call to check. We primarily sell custom and made-to-order windows and doors; fenestration lead times vary based on the product desired. - When should I order windows/doors/brick/stone for my project?

To avoid any unexpected construction delays... as soon as you possibly can! The more time you have, the more options you have, too.

- Do you have [enter brick name here] in stock?